Cultivated meat - grown from animal cells instead of livestock - has the potential to reduce greenhouse gas emissions by up to 92%, use 95% less land, and cut water usage by 78% when produced with renewable energy. However, high production costs, particularly for cell culture media (up to £373 per litre), remain a major barrier. Growth factors, essential proteins for cell growth, account for the bulk of these costs.

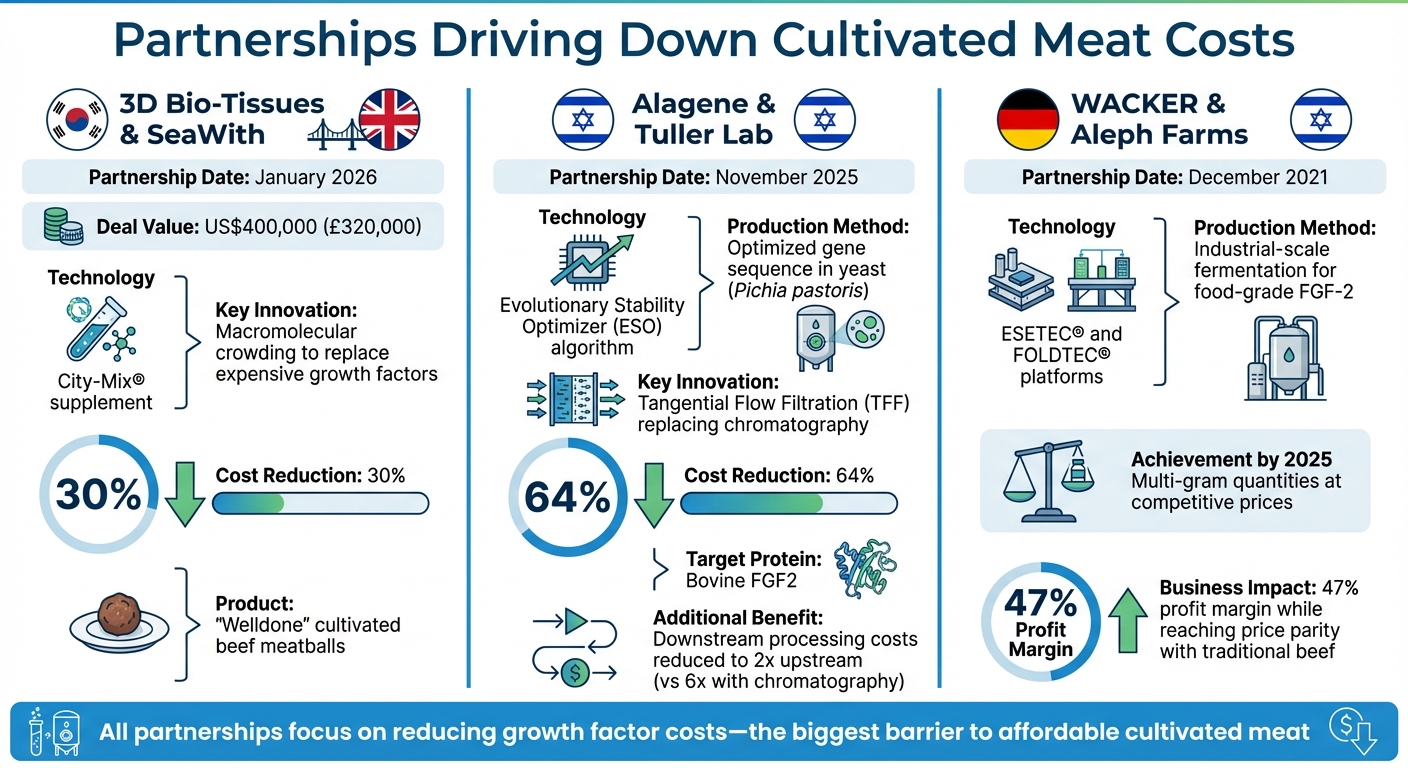

Recent partnerships are tackling this challenge by developing cost-effective methods to produce growth factors and improve production efficiency. Key examples include:

- 3D Bio-Tissues & SeaWith: Reduced costs by 30% using City-Mix® to replace expensive growth factors.

- Alagene & Tuller Lab: Achieved a 64% cost reduction in producing FGF2 using optimised yeast fermentation.

- WACKER & Aleph Farms: Enabled affordable, food-grade FGF2 production, helping Aleph Farms reach price parity with beef.

These efforts are driving cultivated meat closer to affordability, making it a viable option for consumers and a more sustainable alternative to conventional meat.

Growth Factors in Cultivated Meat Production

Why Growth Factors Matter

Growth factors are proteins that act as messengers, instructing cells when to grow and when to specialise into tissues like muscle or fat. Without these signals, animal cells simply won’t grow outside a living organism [3].

"Growth factors are necessary because they provide a signal for cells to grow and differentiate." - Andrew Stout, Lead Researcher, Tufts University [3]

In cultivated meat production, these proteins are crucial. They’re added to a nutrient-rich medium that includes glucose, amino acids, and salts. Key examples include Fibroblast Growth Factor 2 (FGF2), which promotes skeletal muscle cell growth, and Transforming Growth Factor beta (TGFβ), which regulates cell specialisation [2][3]. But the big issue? These proteins are incredibly expensive. For instance, in some serum-free formulations, growth factors like FGF2 can account for up to 60% of the media cost, with total media costs reaching as high as £373 per litre [1][3].

To make cultivated meat commercially viable at around £8 per kilogram, growth factors need to cost about £80,000 per kilogram. This would require a staggering 500- to 1,000-fold reduction in current costs [1][2]. Cutting these costs is absolutely essential for the industry to succeed.

Scaling Growth Factor Production

Reducing the cost of growth factors isn’t just a financial hurdle - it’s a technical one too. Right now, most growth factors are made using pharmaceutical-grade methods. These involve costly microbial fermentation processes followed by extensive purification steps [3].

"It's basically a second upstream 'cultured growth factor' process that is needed to be able to feed your 'cultured meat' process." - Andrew Stout, Lead Researcher, Tufts University [3]

The scale of the challenge is enormous. Capturing just 1% of the global meat market would require millions of kilograms of recombinant proteins [2]. Yet growth factors are expected to make up only 0.02% of the total production volume needed by 2030. This mismatch between demand and cost makes their high price particularly problematic [2]. On top of that, many growth factors currently float freely in the culture medium instead of staying near the cells, leading to unnecessary waste [1]. For more complex products like marbled steaks, this inefficiency makes it even harder to guide different cell types into forming specific patterns [1].

To tackle these challenges, the industry is testing several approaches. These include recycling media, engineering proteins to reduce costs, and attaching growth factors to scaffolds for controlled, long-term release - lasting anywhere from 7 to 28 days [1]. Solving these issues is a critical step towards making cultivated meat more affordable and widely available. Collaborative efforts and innovative production methods are paving the way for these much-needed breakthroughs.

sbb-itb-c323ed3

Dr. Peter Stogios: Low-cost growth factors for serum-free media

Partnerships Reducing Production Costs

Cost Reduction Achievements in Cultivated Meat Production Through Key Partnerships

Collaborations within the cultivated meat industry are making headway in reducing production costs. By pooling expertise, these partnerships are finding ways to improve media efficiency and cell proliferation, addressing some of the biggest cost challenges in the field.

3D Bio-Tissues and SeaWith Partnership

In January 2026, South Korea's SeaWith partnered with UK-based 3D Bio-Tissues, a subsidiary of BSF Enterprise, in a deal worth about US$400,000 (approximately £320,000). 3D Bio-Tissues provides its City-Mix® supplement, which uses macromolecular crowding to replicate dense cell environments. This approach reduces reliance on pricey growth factors and eliminates the need for animal-derived inputs. SeaWith incorporates City-Mix® in producing its "Welldone" cultivated beef products, such as meatballs, aiming for a 30% reduction in production costs [4].

Alagene and Tuller Lab Advancements

In November 2025, Alagene Ltd., led by Neta Agmon, teamed up with the Tuller Lab at Tel Aviv University, headed by Tamir Tuller, to publish research on a scalable method for producing bovine Fibroblast Growth Factor 2 (FGF2). They used the Evolutionary Stability Optimizer (ESO) algorithm to optimise the gene sequence in yeast (Pichia pastoris), replacing expensive chromatography with Tangential Flow Filtration (TFF). This innovation cut production costs by 64% compared to traditional methods [5].

"The filtration-based workflow therefore reduced total production costs by about 64% relative to chromatography." – Gaya Savyon et al., Frontiers in Nutrition [5]

Additionally, TFF brought downstream processing costs down to twice the cost of upstream fermentation, a significant improvement over the sixfold increase seen with chromatography [5].

WACKER and Aleph Farms Collaboration

In December 2021, German chemical company WACKER joined forces with Israeli cultivated meat producer Aleph Farms to optimise growth medium protein production. Using its proprietary ESETEC® and FOLDTEC® platforms, WACKER developed industrial-scale fermentation methods for food-grade FGF-2. By 2025, this collaboration made multi-gram quantities of FGF-2 available at competitive prices [6].

"By producing the necessary components in food-grade quality and in the right quantities, WACKER can help bring down the costs significantly. This approach not only makes cultivated meat more affordable but also paves the way for its large-scale production and commercialisation." – Iris Maria Dahlem, Innovation Manager, WACKER BIOSOLUTIONS [8]

This partnership also supports Aleph Farms in achieving a 47% profit margin while reaching price parity with traditional beef cuts [7].

Future Developments and Industry Effects

New partnerships in the cultivated meat sector are shaking things up. By focusing on cutting costs, these collaborations are helping to shrink the price gap between cultivated meat and traditional meat products. This progress is making cultivated meat more accessible to everyday consumers and setting the stage for broader adoption in the coming years. Recent advances in teamwork and innovation are laying the groundwork for even more affordable options.

Plant-Based Growth Factor Development

Efforts to use plant-based alternatives are significantly reducing the cost of essential production inputs. A standout example is the "Feed for Meat" project, a collaboration between Mosa Meat and Nutreco. In March 2022, this initiative revealed that replacing 99.2% of the basal media (by weight) with food-grade ingredients still maintained the same cell density and muscle cell counts as pharma-grade alternatives [9].

"These results are an industry first, proving that food-grade ingredients perform equivalent to pharma-grade in cell feed. This will represent a significant cost savings as we scale up production." – Maarten Bosch, CEO of Mosa Meat [9]

Common Cost Reduction Strategies

Beyond feed innovations, strategic partnerships are also improving supply chains and standardising nutrient formulations. These efforts are helping to lower production expenses further. As these supply chain efficiencies continue to evolve, the likelihood of seeing cultivated meat more widely available on UK shelves grows stronger.

Conclusion

Collaborative efforts in research are transforming the economics of cultivated meat by swapping costly pharmaceutical-grade ingredients for more affordable, food-grade options. For instance, Mosa Meat and Nutreco achieved an impressive 82% reduction in component costs, while IntegriCulture and the JT Group streamlined their media components from 31 to just 16[10]. These advancements are paving the way for scalable and cost-effective production, inching cultivated meat closer to the £2 per kg target needed to compete with traditional meat[1].

As these cost-saving measures evolve, providing clear and accessible consumer information becomes increasingly important. Platforms like Cultivated Meat Shop simplify the science behind cultivated meat, breaking down innovations in molecular farming, precision fermentation, and food-grade supply chains. By making these advancements understandable, they help consumers see how such breakthroughs are making cultivated meat safer, more accessible, and less expensive. This transparency highlights the ongoing need for research, as further cost reductions are still crucial.

Lowering production costs doesn’t just make cultivated meat commercially viable - it also increases its accessibility to consumers. These collaborative efforts are laying the groundwork for an affordable future, with innovative approaches continuing to drive down expenses. At the same time, educational resources play a key role in connecting advanced biotechnology with everyday shoppers, giving people the knowledge they need to make informed decisions.

The partnerships discussed here underline the power of teamwork. By bringing together research institutions, private companies, and agricultural innovators, the journey to affordable cultivated meat becomes more achievable. Consumer education will remain central to unlocking the full potential of this transformative technology.

FAQs

Why are growth factors so expensive in cultivated meat?

Growth factors are a major expense in cultivated meat production. Proteins such as FGF2 and TGF‑β can cost millions of pounds per gram, while cell culture media can be priced as high as £305 per litre. These elements make up a large share of production costs, posing a significant hurdle in making cultivated meat more affordable.

How do partnerships lower cultivated meat prices?

Partnerships are a game-changer when it comes to cutting the costs of cultivated meat. By pooling resources for research and development, companies can share the financial burden and accelerate progress. These collaborations also help boost production efficiency and reduce the expenses tied to growth media and factors, which are some of the most significant cost drivers.

Beyond shared R&D, teamwork in areas like scaling infrastructure, securing government backing, and tapping into open-source innovations further pushes costs down. Together, these efforts make cultivated meat more accessible and affordable.

When will cultivated meat reach price parity in the UK?

Cultivated meat is projected to match the cost of traditional meat in the UK by the early 2030s. Achieving this will depend on improving production processes and reducing expenses for essential elements like growth factors.